Heat Exchanger Manufacturers in Bhosari

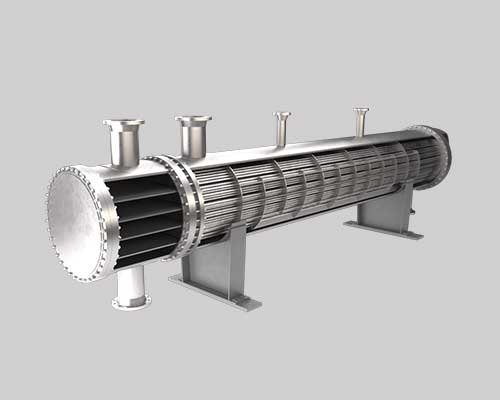

M R Fabrication, founded in 2018 in Pimpri Chinchwad, stands out as a premier Heat Exchanger Manufacturer in Bhosari, offering Industrial Heat Exchangers - also called SS Heat Exchangers or Industrial Heat Exchangers - that balance precision engineering, stringent quality standards, and cost effective performance. Our units are designed under ISO 9001:2015 and ISO 3834 2 welding regimes, stamped U/U2 by PESO for pressure equipment, and built to IS 2825/BIS and ASME VIII codes to ensure reliability across oil & gas, chemical, pharmaceutical, and food & beverage applications. With over 88 projects completed and 85 satisfied clients, our fully automated, vertical shell and tube and plate fin exchangers deliver optimized thermal transfer, reduced downtime, and clear ROI through energy savings and low maintenance requirements.

M R Fabrication: Suppliers, Dealers & Traders in Bhosari

As leading Heat Exchanger Suppliers in Bhosari and Traders, Dealers in Bhosari, we deliver turnkey solutions from AutoCAD/FEA design drawings through fabrication and on‑site commissioning. Our workshop capacity enables batch production of mild steel and stainless steel exchangers - tailored for cosmetics, personal care, and corrosive chemical duties - backed by ISO 14001 environmental and ISO 45001 safety management systems.

Overview: Specifications, Types, Applications & How It Works

Industrial heat exchangers transfer heat between two fluids—liquid or gas—without mixing, via conduction through metal walls that separate the streams. M R Fabrication’s shell‑and‑tube models handle up to 10 bar design pressure and temperatures to 150 °C, with SS 304 construction and turbine or plate‑fin internals for maximum surface area and heat transfer efficiency. Our plate‑fin variants, common in cryogenics and aerospace due to high surface-to-volume ratios, are now adapted for compact industrial processes requiring precise temperature control. Automated PLC controls manage flow rates, pressures, and safety interlocks, while removable bundles and ‘U’‑tube designs facilitate easy maintenance without full system shutdown.

What Is a Heat Exchanger?

A heat exchanger is a device that moves thermal energy between fluids via conductive walls, critical for heating, cooling, condensation, and evaporation in processes like engine cooling, chemical reactors, and HVAC systems. It prevents direct mixing of streams, thus preserving fluid purity and safety in applications ranging from oil refineries to food processing.

Specifications of M R Fabrication Heat Exchangers

| Specification | Details |

|---|---|

| Capacity | 100 L–10 KL |

| Material | SS 304 stainless steel; Mild Steel on request |

| Design Pressure | Up to 10 bar |

| Max. Temperature | 150 °C |

| Automation Grade | Fully automatic PLC control |

| Orientation | Vertical |

| Welding Standard | ISO 3834‑2 |

| Quality Management | ISO 9001:2015 |

| PESO Certification | U/U2 Stamp |

| Plate‑Fin Efficiency | High surface‑to‑volume ratio |

| Maintenance Feature | Removable tube bundles/U‑tube design |

Types of Heat Exchangers

- Shell‑and‑Tube Heat Exchanger: The most common industrial design, featuring tube bundles inside a pressure shell; suited for high‑pressure, high‑temperature duties.

- Plate Heat Exchanger: Uses corrugated metal plates to maximize transfer surface; ideal for compact installations and food‑grade applications.

- Plate‑Fin Heat Exchanger: Incorporates fin structures between plates, offering superior heat transfer in cryogenic or gaseous processes.

- Moving‑Bed Heat Exchanger: Employs granular media for high volumetric transfer in heat recovery, minimizing maintenance costs.

Applications

- Oil & Gas: Condensation and heating of crude feedstocks.

- Chemical & Petrochemical: Reactor jacket cooling, solvent recovery.

- Pharmaceutical: cGMP reactors requiring hygienic, CIP‑compatible exchangers.

- Food & Beverage: Pasteurization and process cooling with stainless‑steel hygiene.

- Personal Care & Cosmetics: Temperature‑controlled mixing of sensitive formulations.

How It Works

Fluids enter separate channels - tube side and shell side (or alternate plates) - and flow in counter‑ or co‑flow arrangements. Heat moves by conduction across metal walls, driven by the temperature gradient. PLC‑monitored valves and sensors adjust flow rates and safety interlocks to maintain optimal ΔT and prevent over‑pressure events.

Ordering, Compliance & Safety

All units come with full documentation. Moreover, we use AutoCAD and FEA drawings. Also, we follow FAT protocols. Furthermore, our certifications include ISO 9001:2015 for Quality Management. Additionally, we have ISO 3834-2 for Welding Quality. Moreover, we hold a PESO U/U2 Stamp under Static & Mobile Vessels Rules, 2016. Also, our materials comply with BIS IS 2825 and IS 6911. Furthermore, we have ISO 14001:2015 for Environmental Management. Additionally, we carry ISO 45001:2018 for Occupational Health and Safety.

For orders, please contact us. You can visit Shop 20, Sr No 120/1B, Chinchwad, Akurdi, near Tulja Bhawani Mandir, Pimpri Chinchwad, Pune – 411019. Alternatively, call +91 97638 85304 or +91 91725 35328. Moreover, you can email us at info@mrfabindia.com.

Why Choose M R Fabrication?

- Proven Expertise: 88+ projects, 85 happy clients showcase reliability.

- Certified Quality: ISO standards and PESO/BIS stamps guarantee compliance.

- Tailored Solutions: Custom internals - baffles, fins, moveable bundles - optimize your process.

- Energy Savings: High‑efficiency designs lower utility costs and carbon footprint.

Get Your Heat Exchanger in Bhosari | M R Fabrication

M R Fabrication is your trusted Heat Exchanger Manufacturer, Supplier, Trader & Dealer in Bhosari, blending local responsiveness with global standards. Request a quote or download our spec sheet today to see how our tailored solutions can maximize your process efficiency.